Best 10 Different Types of Textile Fibers You Should Know About

Textile fibers play a crucial role in the fashion and fabric industry, serving as the fundamental building blocks for a wide range of materials we encounter in our daily lives. Understanding the different types of textile fibers is essential for designers, manufacturers, and consumers alike, as each fiber possesses unique properties that contribute to the characteristics of the final product. As textile expert Dr. Emily Weber states, “The choice of fiber can dramatically influence not only the look and feel of a fabric but also its performance and sustainability.”

In exploring the best 10 different types of textile fibers, we delve into the distinctive qualities and applications of each fiber. From the natural elegance of cotton and silk to the innovative versatility of synthetic fibers, the spectrum of choices available today is vast. Each fiber type brings its own set of advantages and challenges, impacting everything from fashion design to environmental considerations. By increasing our awareness of these fibers, we not only enhance our appreciation of textile arts but also make more informed decisions in our wardrobe choices and purchases.

Types of Natural Fibers: An Overview of their Characteristics

Natural fibers are a cornerstone of the textile industry, prized for their unique characteristics and eco-friendliness. Among the most common types are cotton, linen, wool, silk, and hemp. Cotton stands out for its softness, breathability, and durability, making it an ideal choice for everyday clothing and home textiles. Linen, derived from the flax plant, is known for its strength and moisture-wicking properties, while wool offers excellent insulation and is naturally flame-resistant. Silk, celebrated for its luxurious feel and sheen, provides a lightweight option for delicate fabrics. Meanwhile, hemp is gaining popularity for its sustainability, being both strong and biodegradable.

When working with natural fibers, consider a few tips to enhance your experience. First, always check the fiber content to understand its care requirements better; for instance, silk and wool often require more delicate handling than cotton or linen. Additionally, when dying natural fibers, use natural dyes to maintain their eco-friendly charm and ensure vibrant, long-lasting colors. Lastly, mixing different natural fibers can provide unique textures and performance characteristics in your textile projects, giving rise to innovative and sustainable creations.

Understanding Synthetic Fibers: Features and Applications

Synthetic fibers play a crucial role in modern textiles, offering a wide range of features and applications that make them highly versatile. Unlike natural fibers, which are derived from plants or animals, synthetic fibers are man-made through chemical processes, resulting in materials that often exhibit enhanced durability, resistance to moisture, and affordability. Common examples include polyester, nylon, and acrylic, each bringing unique benefits tailored to various uses in fashion, upholstery, and industrial applications.

When considering synthetic fibers for your next project, keep a few tips in mind. First, assess the end-use requirements: for activewear, look for moisture-wicking properties, while upholstery might benefit from stain resistance. Second, understanding the environmental impact of synthetic fibers is essential; opting for recycled materials can significantly reduce your carbon footprint. Lastly, always consider the care instructions—some synthetic fabrics are easy to maintain, while others might require special handling to preserve their appearance and functionality.

Whether it's for clothing, home textiles, or specialty applications, understanding the features and benefits of synthetic fibers can help you make informed decisions. Their adaptability, paired with advancements in technology, continues to expand their usage in numerous fields, highlighting the importance of acknowledging this integral component of the textile industry.

Best 10 Different Types of Textile Fibers You Should Know About - Understanding Synthetic Fibers: Features and Applications

| Fiber Type | Features | Applications |

|---|---|---|

| Polyester | Durable, wrinkle-resistant, quick-drying | Clothing, upholstery, outdoor gear |

| Nylon | Strong, elastic, resistant to abrasion | Swimwear, activewear, carpets |

| Acrylic | Lightweight, soft, often used as wool substitute | Sweaters, blankets, fleece |

| Spandex | Highly elastic, durable | Activewear, swimwear, undergarments |

| Rayon | Soft, breathable, drapes well | Dresses, linings, home textiles |

| Modal | Soft, luxurious feel, biodegradable | Lingerie, sportswear, bed sheets |

| Acetate | Silky appearance, good drape | Linings, evening wear, ribbons |

| Polypropylene | Water-resistant, lightweight | Outdoor clothing, carpets, insulation |

| Tencel (Lyocell) | Eco-friendly, soft, moisture-wicking | Shirts, dresses, activewear |

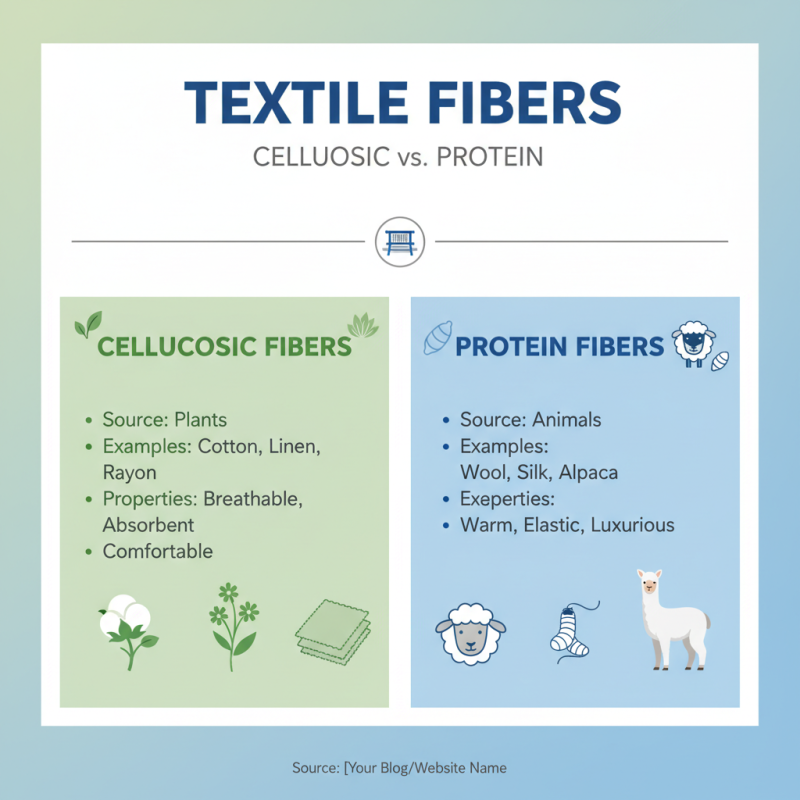

Comparing Cellulosic and Protein Fibers in Textile Production

Cellulosic and protein fibers are two primary categories of textile fibers that play a crucial role in textile production. Cellulosic fibers, derived from plants, encompass materials like cotton, linen, and rayon. These fibers are known for their breathability, moisture absorption, and comfort, making them ideal for clothing. On the other hand, protein fibers, sourced from animal products, include wool, silk, and alpaca. These fibers are praised for their warmth, elasticity, and luxurious feel, often used in high-quality garments.

When comparing these two fiber types, it’s essential to consider their environmental impact. Cellulosic fibers can be more sustainable if sourced from eco-friendly crops, while protein fibers generally require more resource-intensive processes for production. Additionally, cellulosic fibers are often biodegradable, but their issue of pesticide use in conventional farming practices can raise concerns.

**Tips for Choosing the Right Fiber:**

1. Consider your needs: Look for cellulosic fibers if you prioritize comfort and breathability, while protein fibers may be better for warmth and luxury.

2. Check for sustainability: Investigate how the fibers are produced to make environmentally responsible choices, particularly focusing on organic or sustainably sourced options.

3. Be mindful of care: Different fibers require different care methods, so make sure to choose fibers that fit your lifestyle and maintenance preferences.

Exploring Specialty Fibers: Innovations in Textile Technology

In recent years, the textile industry has witnessed remarkable innovations, particularly in the realm of specialty fibers. These advanced materials not only enhance the aesthetic qualities of textiles but also improve their functional attributes. For instance, bioengineered fibers derived from organic materials have emerged, enabling the creation of fabrics that are not only sustainable but also biodegradable. These fibers cater to the growing demand for environmentally friendly textiles, thus marking a significant shift towards a more sustainable future.

Furthermore, innovations such as moisture-wicking and temperature-regulating fibers have transformed activewear and outdoor clothing. These specialty fibers, developed through cutting-edge technology, provide comfort and performance by effectively managing sweat and body temperature. Other advancements include the incorporation of antimicrobial properties into fibers, which help inhibit the growth of odor-causing bacteria, thus extending the lifespan of garments. As research and development continue to push the boundaries of textile technology, the integration of specialized fibers will play a pivotal role in shaping the future of the industry.

Best 10 Different Types of Textile Fibers You Should Know About

The Role of Fiber Blends in Modern Textile Manufacturing

Fiber blends play a crucial role in modern textile manufacturing, combining different types of fibers to enhance performance and aesthetics. By leveraging the unique properties of various fibers, manufacturers can create fabrics that offer improved durability, comfort, and functionality. For instance, blending natural fibers like cotton with synthetic fibers such as polyester can yield a fabric that is not only soft and breathable but also wrinkle-resistant and quick-drying. This approach allows for greater versatility in meeting consumer demands for both practicality and style.

Moreover, the use of fiber blends enables manufacturers to innovate in response to evolving trends in the fashion industry. As consumers increasingly seek sustainable and eco-friendly options, blends that incorporate recycled fibers or organic materials are becoming more prevalent. Additionally, blending fibers can also optimize production processes, allowing manufacturers to efficiently utilize resources while maintaining high-quality outcomes.

Ultimately, the strategic combination of different textile fibers drives advancements in textile technology, fostering an environment where creativity and functionality coexist harmoniously.

Related Posts

-

Exploring the Different Types of Textile Fibers: A 2025 Guide to Fabrics

-

10 Best Practices in Textile Manufacturing for Sustainable Production

-

Top Benefits of Using Pet Fiber for Your Furry Friends Health and Comfort

-

Top 10 Benefits of Using Acrylic Textile in Fashion and Home Decor

-

10 Essential Tips for Choosing the Right Staple Fibers for Your Projects

-

Best Staple Yarns for Knitting and Crochet Projects in 2023