10 Best Practices in Textile Manufacturing for Sustainable Production

The textile manufacturing industry is a pivotal segment of the global economy, accounting for approximately $920 billion in market value as of 2021 and projected to reach around $1.23 trillion by 2025. However, the rapid growth of this industry has led to significant environmental and social challenges, prompting a shift towards more sustainable production practices. As textiles account for 10% of global carbon emissions and are a leading contributor to water pollution, the urgency for sustainable methods has never been more critical.

In response to these pressing issues, industry stakeholders are increasingly adopting best practices tailored to promote sustainability in textile manufacturing. This includes optimizing resource use, reducing waste, and implementing eco-friendly materials throughout the production process. According to the Sustainable Apparel Coalition, a collaborative effort of various stakeholders in the apparel and footwear industries, adopting sustainable practices can reduce environmental impacts while enhancing brand reputation and consumer loyalty.

This introduction outlines the importance of sustainable practices in textile manufacturing, highlighting the need for innovation and responsibility within the industry. By adhering to best practices, manufacturers can contribute to a more sustainable future while meeting the growing demand for environmentally conscious products from consumers worldwide.

Sustainable Sourcing of Raw Materials in Textile Manufacturing

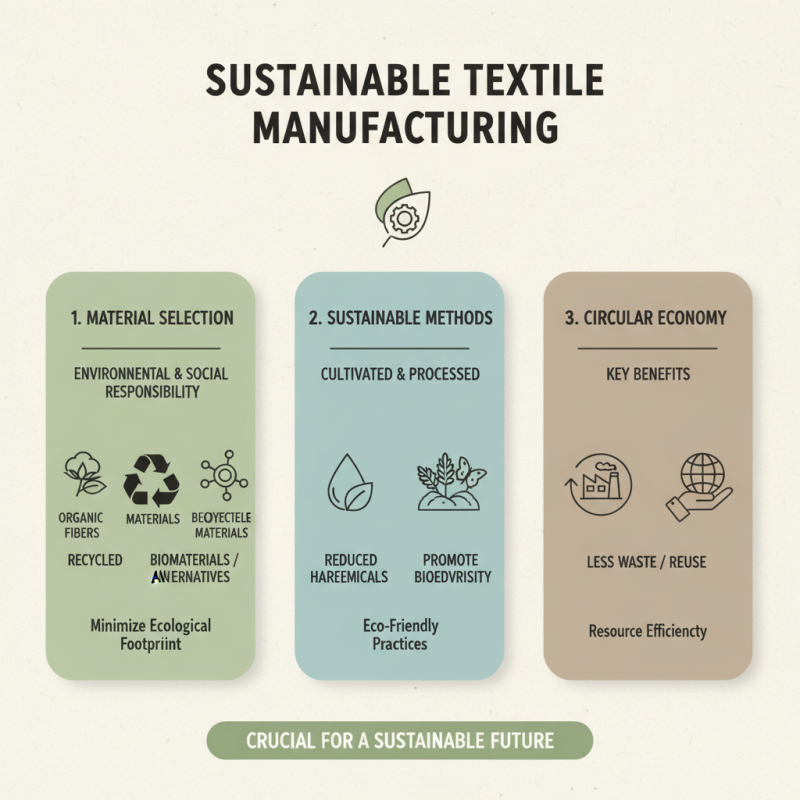

Sustainable sourcing of raw materials is a crucial element in achieving sustainability in textile manufacturing. The production process begins with the selection of materials, where the emphasis must be on environmental and social responsibility. This involves opting for organic fibers, recycled materials, and innovative alternatives such as biomaterials, which minimize ecological footprints and foster a circular economy. By seeking raw materials that are cultivated or processed using sustainable methods, manufacturers can reduce their reliance on harmful chemicals and promote biodiversity.

Additionally, establishing strong relationships with suppliers who adhere to sustainable practices is essential for successful sourcing. Engaging in transparent and ethical procurement processes not only ensures that the materials are responsibly sourced but also upholds fair labor practices throughout the supply chain. Implementing rigorous standards and traceability measures can help manufacturers assess the sustainability credentials of their suppliers. This kind of accountability not only enhances brand reputation but also contributes to the overall resilience of the textile industry in an era increasingly focused on sustainability and ethical consumption.

Implementing Energy-Efficient Technologies in Production Processes

Implementing energy-efficient technologies in textile manufacturing is a critical step towards achieving sustainable production. The textile industry is traditionally known for its high energy consumption and environmental impact. By integrating energy-efficient machinery and processes, manufacturers can significantly reduce their carbon footprint while maintaining productivity. Technologies such as automatic looms and energy-efficient dyeing machines not only enhance operational efficiency but also minimize resource wastage. Additionally, leveraging smart manufacturing practices, such as real-time monitoring of energy usage, allows for better management of resources and reduces unnecessary consumption.

Another key aspect is the adoption of renewable energy sources, such as solar or wind power, within production facilities. Utilizing these sustainable energy options can drastically lower reliance on fossil fuels, promoting a cleaner production environment. Furthermore, investing in energy-efficient lighting and HVAC systems can improve the overall energy efficiency of textile manufacturing plants. These upgrades, while initially requiring capital investment, can lead to substantial long-term savings and contribute to a more sustainable business model, creating a positive impact on the environment and enhancing the overall competitiveness of textile producers in the market.

10 Best Practices in Textile Manufacturing for Sustainable Production - Implementing Energy-Efficient Technologies in Production Processes

| Best Practice | Description | Benefits | Energy Savings (%) | Implementation Cost ($) |

|---|---|---|---|---|

| Use of Solar Power | Integrating solar energy systems into production facilities. | Reduces carbon footprint, low operational costs. | 40% | 15,000 |

| Energy-Efficient Machinery | Updating to machines that consume less power. | Lower energy bills, improved production capacity. | 30% | 25,000 |

| Waste Heat Recovery | Utilizing waste heat from machinery to power other processes. | Increased overall efficiency, reduced waste. | 25% | 20,000 |

| LED Lighting | Switching to LED lighting in facilities. | Lower electricity costs, longer lifespan than traditional bulbs. | 20% | 2,000 |

| Eco-Friendly Dyes | Using natural or low-impact dyes in production. | Reduced chemical waste, better for the environment. | N/A | 5,000 |

| Automated Production | Implementing automation to streamline production processes. | Increased efficiency, reduced manual labor. | 35% | 50,000 |

| Water Management Systems | Implementing systems to recycle and reuse water. | Saves water, lowers treatment costs. | N/A | 30,000 |

| Sustainable Materials | Utilizing materials sourced from sustainable practices. | Supports eco-friendly practices, improves brand image. | N/A | 10,000 |

| Employee Training Programs | Training employees on sustainability practices. | Increased awareness, improved operational practices. | N/A | 15,000 |

Reducing Water Usage and Promoting Water Conservation Techniques

Textile manufacturing is notorious for its considerable water demand, contributing to environmental degradation and resource depletion. According to a report by the World Resources Institute, the fashion industry is responsible for nearly 20% of global wastewater, largely due to water-intensive processes in dyeing and finishing fabrics. To combat this issue, manufacturers are increasingly adopting innovative water conservation techniques. For instance, closed-loop water systems are becoming standard in many facilities, allowing the recycling of water used in production processes. This not only minimizes water withdrawal but also reduces wastewater generation significantly.

Moreover, implementing water-efficient technologies can lead to substantial reductions in overall consumption. A recent study by the Sustainable Apparel Coalition revealed that brands integrating water-saving technologies saw a reduction in water usage by up to 30% without compromising product quality. Rainwater harvesting systems are also gaining traction, enabling manufacturers to supplement their water supply and lessen dependency on municipal sources. By prioritizing water conservation strategies, textile manufacturers not only decrease their environmental footprint but also enhance their operational efficiencies, aligning with the growing consumer demand for sustainability in the fashion industry.

Water Usage Reduction Techniques in Textile Manufacturing

Minimizing Waste through Recycling and Upcycling Initiatives

In the realm of textile manufacturing, sustainability has become an essential focus, particularly through the lens of recycling and upcycling initiatives. By minimizing waste, manufacturers can reduce their environmental footprint while creating innovative products. One effective strategy is to implement a closed-loop system, where post-consumer textiles are collected and transformed into new fibers. This approach not only diverts waste from landfills but also conserves natural resources used in the production of new materials.

**Tip:** Explore partnerships with local organizations that specialize in recycling textiles. Collaborating can enhance collection efforts and promote community engagement, turning waste into a valuable resource.

Additionally, upcycling offers a creative avenue for sustainability. Instead of discarding excess fabric or incomplete garments, manufacturers can repurpose these materials into new, fashionable items or accessories. This practice not only addresses waste management but also elevates brand image by showcasing a commitment to environmental responsibility while appealing to eco-conscious consumers.

**Tip:** Host workshops or design contests aimed at upcycling fabric scraps. This not only inspires creativity within the team but also fosters a culture of sustainability in your organization.

Enhancing Supply Chain Transparency and Ethical Labor Practices

In today's textile manufacturing landscape, ensuring supply chain transparency and ethical labor practices is more important than ever. Brands and manufacturers must adopt sustainable practices that not only reduce environmental impact but also promote fair treatment of workers throughout the production process. By enhancing supply chain transparency, manufacturers can create a more trustworthy relationship with consumers who are increasingly aware of where and how their clothing is made.

One effective strategy is to implement comprehensive traceability systems that monitor every step of the supply chain, from raw material sourcing to final production. This can include utilizing blockchain technology which provides a secure and immutable record of each transaction, making it easier to verify the origin of materials and labor conditions. Additionally, companies should regularly conduct audits and assessments of their suppliers to ensure compliance with ethical labor practices, ensuring that workers receive fair wages, safe working conditions, and the right to collective bargaining.

Tips for achieving this include establishing clear communication channels with suppliers about ethical standards and expectations. Create an accountability framework that encourages reporting and addressing any labor violations. Moreover, engaging in partnerships with NGOs can help in better understanding local labor practices and enhancing educational programs for workers, ultimately fostering an environment of respect and integrity in the textile manufacturing process.

Related Posts

-

Exploring the Future of Textile Manufacturing: Sustainable Innovations Revolutionizing the Industry

-

Top Challenges in Textile Manufacturing and How to Overcome Them

-

2025 Top 5 Innovations Transforming the Textile Industry You Need to Know

-

10 Essential Tips for Choosing the Right Staple Fibers for Your Projects

-

Top 5 Benefits of Polyester Fiber for Home and Industrial Use

-

Top 10 Acrylic Fiber Innovations to Look Out for in 2025