How to Identify Different Types of Textile Fibers for Your Projects

The textile industry has experienced significant advancements and changes over the years, necessitating a deeper understanding of different types of textile fibers among creators and manufacturers. According to a report by the Textile World, the global textile fiber market is expected to reach approximately 100 million metric tons by 2024, driven by increasing demand for high-quality materials across various sectors. This remarkable growth highlights the importance of accurately identifying different types of textile fibers, as each type possesses unique properties and applications that can greatly influence the outcome of fabric production and design.

Understanding the characteristics of different types of textile fibers not only aids in selecting the best materials for specific projects but also contributes to sustainability efforts within the industry. The 2022 Global Sustainability Report indicates that choosing the right fiber can significantly reduce environmental impact, with certain fibers requiring less water and energy during production. By mastering the identification and application of these fibers, professionals in the textile arena can enhance the quality and sustainability of their products, ultimately meeting consumer demands for both performance and ecological considerations.

Understanding the Basics of Textile Fibers and Their Characteristics

Textile fibers can be broadly categorized into two main types: natural and synthetic. Natural fibers, such as cotton, wool, and silk, originate from plants and animals. Cotton, for instance, is one of the most widely used fibers, accounting for approximately 30% of global textile production, as per a report by the International Cotton Advisory Committee. It is valued for its softness, breathability, and versatility in various applications. Wool, on the other hand, offers excellent insulation and moisture-wicking properties, making it ideal for cold-weather garments. The fiber's inherent elasticity enhances its durability, showcasing the unique benefits of natural fibers.

On the other hand, synthetic fibers, including polyester and nylon, are derived from chemical processes. They have gained significant traction in the textile industry, comprising around 70% of all fiber production, according to the Textile Exchange's 2021 report. Polyester, for example, is celebrated for its high strength, resistance to wrinkles, and quick-drying capabilities. Additionally, the rise of recycled polyester initiatives reflects an increasing trend towards sustainability within synthetic fiber usage. Understanding these fundamental characteristics of textile fibers not only aids in selecting the right materials for projects but also emphasizes the ongoing evolution within the textile industry, where sustainability and functionality play vital roles.

How to Identify Different Types of Textile Fibers for Your Projects

| Fiber Type | Source | Properties | Common Uses |

|---|---|---|---|

| Cotton | Natural | Soft, breathable, absorbent | Clothing, bed linens, towels |

| Wool | Natural | Warm, elastic, water-resistant | Sweaters, blankets, carpets |

| Silk | Natural | Lustrous, smooth, strong | Luxury clothing, ties, upholstery |

| Polyester | Synthetic | Durable, wrinkle-resistant, easy care | Activewear, home furnishings, jackets |

| Nylon | Synthetic | Strong, elastic, absorbs moisture | Activewear, stockings, ropes |

Natural vs. Synthetic Fibers: Key Differences Explained

When choosing textile fibers for your projects, understanding the fundamental differences between natural and synthetic fibers is crucial. Natural fibers, derived from plants, animals, or minerals, offer unique characteristics that make them suitable for various applications. For example, cotton, a widely known natural fiber, is prized for its softness and breathability, making it ideal for comfortable clothing. Wool, another natural option, provides excellent insulation, making it popular in colder climates. These fibers typically have a lower environmental impact than synthetic options, as they are biodegradable and renewable.

On the other hand, synthetic fibers are man-made, typically derived from chemical processes. Materials like polyester and nylon are examples of synthetic fibers that are known for their durability and resistance to wrinkles and stains. These fibers are engineered to offer specific qualities; for instance, polyester is often chosen for its moisture-wicking properties, making it favorable for activewear. However, the production of synthetic fibers can have a significant ecological footprint due to the use of petroleum-based resources. Additionally, they are not biodegradable, contributing to long-term waste issues. Understanding these differences can help you make informed choices tailored to the needs of your project while considering environmental implications.

Identifying Popular Animal-Based Textile Fibers

Animal-based textile fibers are renowned for their unique properties and variety, often adding warmth, durability, and a luxurious feel to various projects. The most common types include wool, silk, and alpaca fibers, each offering distinct characteristics that can influence your choice based on the needs of your project. Wool, derived primarily from sheep, is celebrated for its insulation, elasticity, and resilience. Its natural crimp gives it the ability to trap air, providing excellent warmth even when wet, making it ideal for winter garments and cozy blankets.

Silk, on the other hand, is produced by silkworms and is prized for its sheen and softness. It is strong yet lightweight, imparting an elegant drape, which is perfect for formal wear and accessories. Additionally, silk has natural moisture-wicking properties that help regulate temperature, making it suitable for any season. Alpaca fibers, sourced from the South American alpaca, are another excellent choice, known for their hypoallergenic qualities and silky texture. They come in a range of natural colors and provide superior warmth without the itchiness commonly associated with wool. Understanding these fibers' specific qualities allows crafters and designers to select the best material for their textile projects, ensuring both functionality and aesthetic appeal.

Identifying Popular Animal-Based Textile Fibers

This chart illustrates the strength of different popular animal-based textile fibers measured in grams per denier. Understanding these properties can help you choose the right fiber for your textile projects.

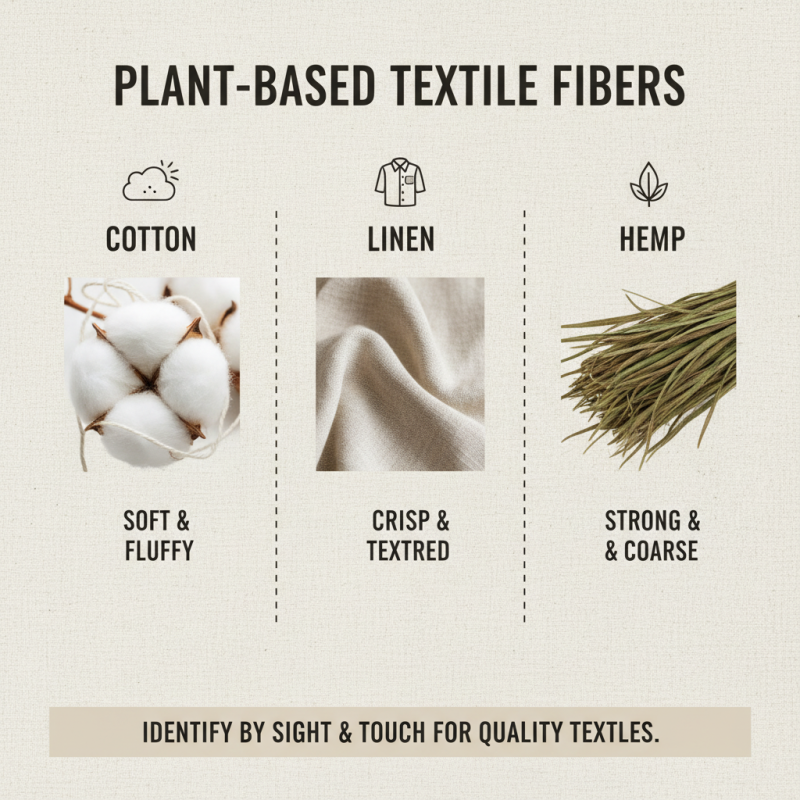

Recognizing Plant-Based Textile Fibers by Appearance and Touch

When working on textile projects, recognizing plant-based fibers by their appearance and touch is crucial for selecting the right material. Plant-based fibers such as cotton, linen, and hemp each have distinct characteristics. For instance, cotton is soft and fluffy, whereas linen has a crisp, slightly textured feel. Hemp fibers tend to be stronger and coarser, with a natural sheen that sets them apart. Observing these tactile and visual cues will allow you to curate fabrics that not only meet your needs but also enhance the overall quality of your work.

**Tips:** One effective way to differentiate between these fibers is to conduct a simple burn test at home. When burned, cotton will leave behind a soft ash, while linen burns quickly with a natural smell. Hemp can be identified by its tougher nature, producing a more fibrous ash. Additionally, make a habit of touching and feeling the fabrics; pay attention to the texture and weight you prefer for your projects. Always remember that practice makes perfect, so handle various types of textile fibers to develop your sensitivity over time.

Moreover, visual inspection plays a critical role as well. Look for the fiber’s luster, color variations, and weave. For instance, cotton tends to have a uniform and soft sheen, while linen possesses a more rustic look, often with irregularities. These features not only help in identifying the fiber but also inspire creative choices tailored to your project's aesthetic. Engaging in these practices will ultimately deepen your understanding and appreciation of plant-based textile fibers in your crafting endeavors.

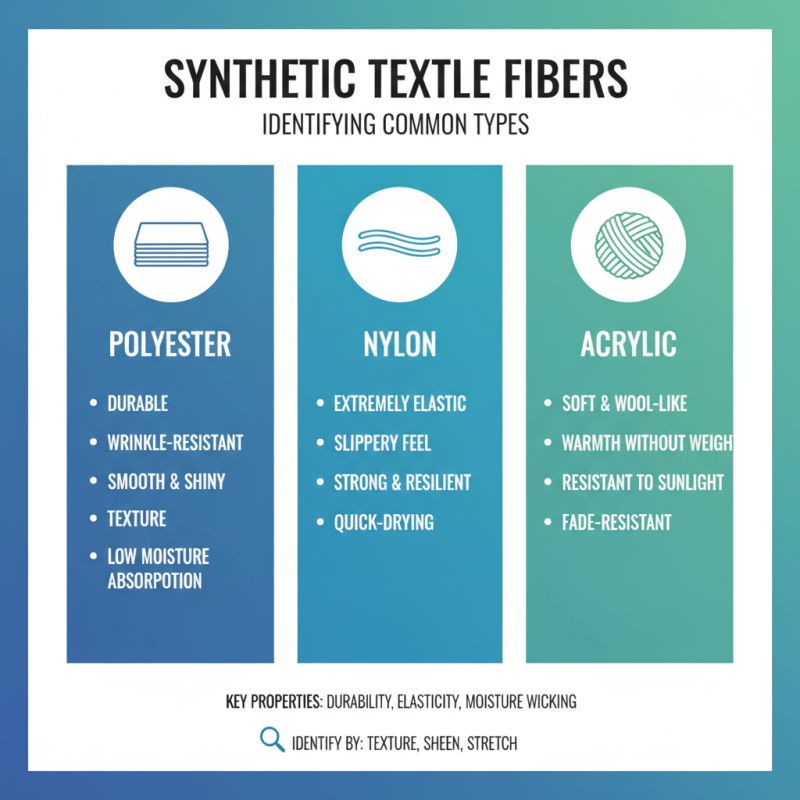

Common Synthetic Fibers: Features and Identification Techniques

When working with textile fibers, it's essential to understand the common types of synthetic fibers, as they are widely used in various projects due to their unique properties. Synthetic fibers, such as polyester, nylon, and acrylic, offer advantages like durability, resistance to wrinkles, and low moisture absorption. To effectively identify these fibers, one can look at their texture, sheen, and elasticity. For instance, polyester typically has a smooth and shiny surface, while nylon feels slippery and is highly elastic, stretching back to its original shape when pulled.

Identification techniques for synthetic fibers include visual inspection and burn tests. Visual inspection involves examining the fiber’s appearance and comparing it to known examples of synthetic textiles. A burn test can provide further insight; when heated, polyester melts and forms a hard bead, whereas nylon will burn with a chemical smell and leave a sticky residue. Understanding these features and techniques can significantly aid in selecting the right fiber type for specific applications, enabling better outcomes in textile projects.

Related Posts

-

Exploring the Different Types of Textile Fibers: A 2025 Guide to Fabrics

-

Best 10 Different Types of Textile Fibers You Should Know About

-

How to Identify Different Types of Textile Fibers for Your Sewing Projects

-

10 Best Practices in Textile Manufacturing for Sustainable Production

-

2025 Top 5 Innovations Transforming the Textile Industry You Need to Know

-

Exploring the Future of Textile Manufacturing: Sustainable Innovations Revolutionizing the Industry