How to Identify Different Types of Polyester and Their Uses?

Polyester is a versatile synthetic fiber widely used in various industries, from textiles to packaging. Understanding the different types of polyester is crucial for selecting the right material for specific applications. According to a 2022 industry report by Smith Textile Research, polyester accounts for around 52% of the global fiber market.

Experts emphasize the importance of recognizing these variations. Dr. Emily Foster, a leading materials scientist, states, "Different types of polyester serve unique functions and qualities in numerous applications." For instance, PET, or polyethylene terephthalate, is prominent in beverage bottles, while microfibers are favored in cleaning products.

Despite its popularity, many people overlook the nuances of polyester types. Lack of awareness may lead to suboptimal material choices. Choosing the right polyester is not always straightforward, and frequent mistakes occur in this complex field. Increased education on the different types of polyester is essential for both consumers and manufacturers to ensure effectiveness and sustainability in product development.

Types of Polyester: An Overview of Varieties and Characteristics

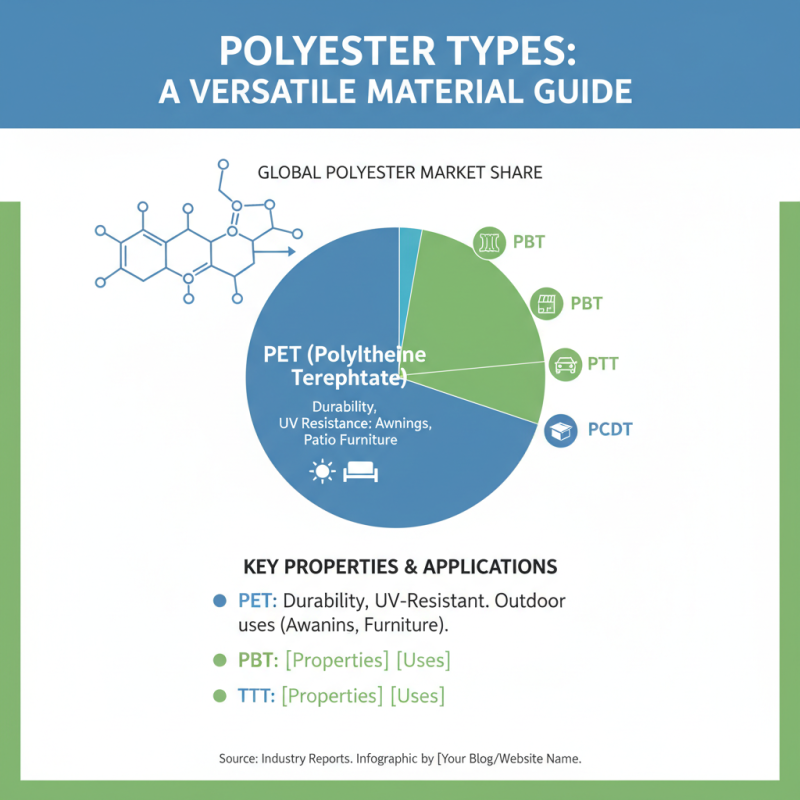

Polyester is a versatile synthetic fabric. Several types of polyester exist, each with unique properties. The most common types include PET (Polyethylene Terephthalate), PCDT (Polycyclohexylene Dimethylene Terephthalate), and bio-based polyesters. PET is widely used for clothing and home textiles. It resists wrinkles and holds its shape well.

PCDT is known for its stretchability and softness. These qualities make it ideal for activewear and performance apparel. According to industry reports, the global demand for polyester is expected to grow by 4% annually. This trend reflects its popularity in various sectors, from fashion to automotive.

While polyester offers numerous advantages, it also has drawbacks. For example, it is not biodegradable. Concerns about environmental impact are growing. As consumers become more eco-conscious, the need for sustainable alternatives increases. There is ongoing research into bio-based polyesters to address these issues. However, the scalability of such solutions is still a question mark in the industry.

Key Properties of Different Polyester Types and Their Applications

Polyester is a versatile material with various types, each serving distinct purposes. Understanding the key properties of these polyester types can guide their effective application across industries. For example, PET (Polyethylene Terephthalate) is widely recognized for its excellent durability and resistance to UV light. This makes it suitable for outdoor products, such as awnings and patio furniture. Industry reports indicate that PET accounts for nearly 70% of the global polyester market, reflecting its popularity.

Another type, PCT (Polycyclohexylene Dimethylene Terephthalate), offers superior thermal stability and can withstand higher temperatures compared to PET. This property makes it ideal for automotive components and electrical applications, which require materials that can perform under stress. Research suggests that the demand for PCT is rising, with a projected growth of 4.5% annually through 2028, highlighting its emerging role in advanced applications.

While these properties make polyester materials attractive, challenges remain. Some polyester types can be less biodegradable, raising environmental concerns. Efforts are underway to develop more sustainable polyester variants, yet the transition is slow. Industry surveys indicate that only about 30% of manufacturers are actively pursuing eco-friendly alternatives. The journey towards more sustainable solutions still requires significant reflection and innovation.

Common Uses of Polyester in Textiles and Apparel Manufacturing

Polyester is a versatile synthetic fiber widely used in textiles and apparel manufacturing. It accounts for around 52% of the global fiber market, according to the World Textile Organization. This staggering percentage showcases its popularity in clothing production and home textiles. Polyester's unique qualities, such as durability and wrinkle resistance, make it a preferred choice for various applications.

In clothing, polyester blends are common. These blends enhance functionality and comfort. For instance, activewear often includes polyester for moisture-wicking properties. The fabric dries quickly, which is essential for athletic activities. A report from Statista indicates that the global polyester apparel market is projected to reach $88 billion by 2025. This growth reflects the increased demand for lightweight and functional clothing.

However, the environmental impact of polyester is a significant concern. It is derived from petroleum, a non-renewable resource. Recycling polyester is possible but not widely practiced. According to a study by the Journal of Cleaner Production, only 14% of polyester is recycled into new fabrics. This low figure highlights the need for better recycling systems. The industry must respond to these challenges to ensure a sustainable future while meeting consumer demands.

Industrial Applications of Polyester: Beyond Fabrics and Fashion

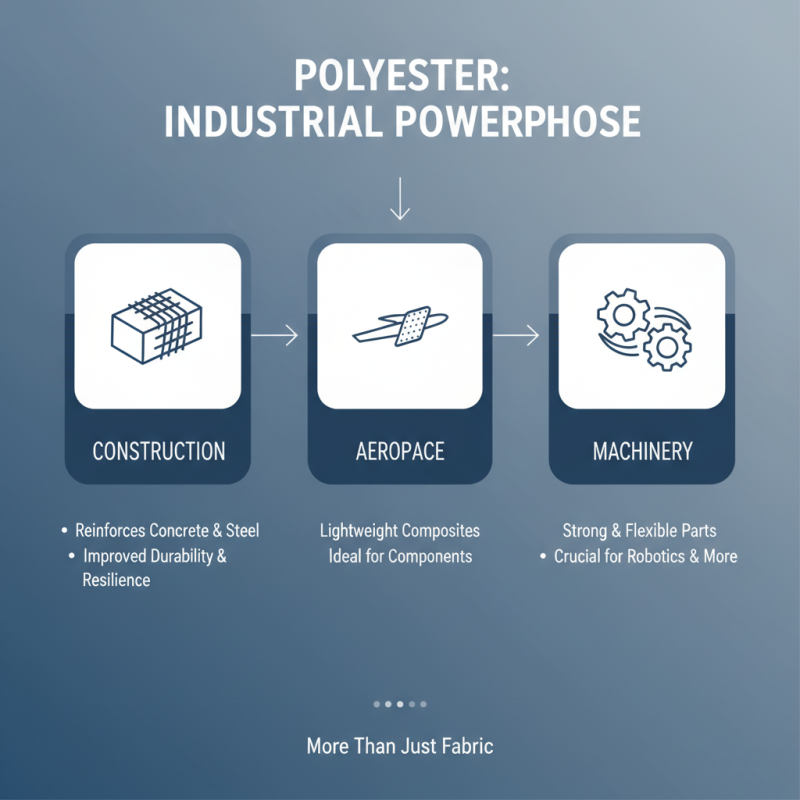

Polyester is more than just a fabric. Its versatility allows it to be used in various industrial applications. In construction, polyester fibers reinforce materials like concrete and steel. This improves durability and resilience, essential for modern buildings. Additionally, polyester composites are lightweight, making them ideal for aerospace components. They are strong yet flexible, crucial for machinery parts.

In the automotive sector, polyester serves as a key component. It is often found in interior parts such as seat covers and dashboards. These polyester products resist wear and tear, enhancing vehicle longevity. However, the environmental impact of plastic production raises questions. Recycling polyester is challenging and often neglected.

Polyester finds use in medical applications too. Surgical sutures made from polyester are strong and reliable. They help in wound closure, ensuring patients heal properly. Despite these advantages, the sustainability of polyester remains a concern. Finding ways to repurpose and recycle this material is still a work in progress. It's essential for industries to reflect on these challenges as they continue to innovate.

Identifying Polyester Types through Labeling and Fiber Testing Techniques

Identifying the types of polyester can be complex. Labels often provide key insights. They usually indicate the blend and percentage of fibers. Common types include PET, PBT, and PLA. Each type has distinct characteristics. For instance, PET is widely used in clothing. Reports state it accounts for 48% of global fiber production. PBT, known for its elasticity, is often utilized in activewear.

Fiber testing techniques are crucial for accurate identification. Techniques like Fourier Transform Infrared Spectroscopy (FTIR) help discern polyester types. This method analyzes the chemical structure of fibers. However, many overlook this technical detail. Simple burn tests can also reveal polyester types. They emit a sweet odor when burned, which hints at their chemical nature.

Awareness of these differences is essential for consumers and manufacturers. Not every labeling is straightforward. Misleading information can confuse buyers. Additionally, understanding these fibers’ applications is vital. Some are better suited for industrial uses, while others excel in fashion. A deeper exploration of labels can reveal both professional and practical insights.

Related Posts

-

Why Are There Different Types of Polyester and What Are Their Uses

-

Exploring the Future of Textile Manufacturing: Sustainable Innovations Revolutionizing the Industry

-

How to Use Staple Fibers in Textile Production?

-

2025 How to Choose the Best Yarn Acrylic for Your Next Knitting Project

-

2025 Top 5 Innovations Transforming the Textile Industry You Need to Know

-

Top 10 Benefits of Using Acrylic Textile in Fashion and Home Decor