What is the Impact of Technology on the Textile Industry Today

The textile industry is undergoing a significant transformation, driven by rapid advancements in technology. From the introduction of automated manufacturing processes to innovative materials and sustainable practices, technology is reshaping how textiles are produced, distributed, and consumed. This profound impact not only enhances efficiency and productivity but also addresses the growing demand for sustainability in a world increasingly concerned about environmental issues.

As the textile industry embraces digitalization, we see the rise of smart fabrics, 3D printing, and data analytics, all of which contribute to a more agile and responsive marketplace. Enhanced connectivity through the Internet of Things (IoT) enables manufacturers to optimize their supply chains, reduce waste, and meet the dynamic preferences of consumers. Moreover, technology facilitates a new era of customization, where individuals can create unique textile products tailored to their personal styles and needs.

In conclusion, the influence of technology on the textile industry is multifaceted, opening doors to innovation while challenging traditional practices. As stakeholders navigate this evolving landscape, the focus will increasingly be on how to harness technological advancements responsibly and sustainably to ensure the industry's future growth and resilience.

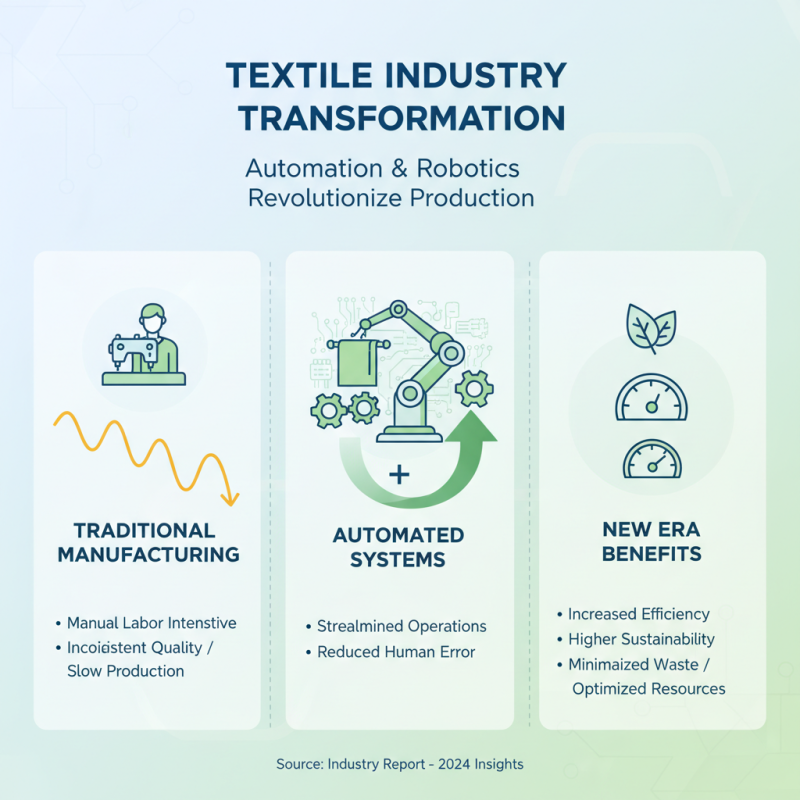

Impact of Automation and Robotics on Textile Production Efficiency

The textile industry is undergoing a significant transformation due to advancements in automation and robotics, which are enhancing production efficiency like never before. Traditional manufacturing processes often require a substantial amount of manual labor, which can lead to inconsistent product quality and slow production rates. However, with the introduction of automated systems, companies can streamline their operations, reduce human error, and achieve higher sustainability by minimizing waste and optimizing resource use.

Automation not only speeds up production times but also allows for the customization of textiles on a scale that was previously unimaginable. Robotics can handle complex tasks such as cutting, sewing, and finishing with precision, enabling companies to quickly adapt to changing consumer demands. This flexibility paired with efficiency ensures that textile producers can maintain a competitive edge in a fast-paced market.

**Tips for Implementing Automation:**

1. Start with a clear assessment of your current processes to identify areas where automation can add value.

2. Invest in training for your workforce to bridge the gap between traditional skills and new technological competencies.

3. Consider gradual integration of robotic solutions, allowing for adjustments based on real-time performance and feedback.

By embracing these innovations, the textile industry not only boosts its productivity but also paves the way for a more efficient and responsive manufacturing environment.

Role of Smart Fabrics and Wearable Technology in Modern Fashion

The integration of smart fabrics and wearable technology is radically transforming the textile industry, particularly in the realm of modern fashion. According to a report by MarketsandMarkets, the global smart textiles market is projected to grow from $1.8 billion in 2021 to $6.2 billion by 2026, with a compound annual growth rate (CAGR) of 28.9%. This rapid growth reflects the increasing consumer demand for innovative clothing that offers enhanced functionality and connectivity, thereby revolutionizing the way we perceive fashion.

Smart fabrics, designed with advanced materials that interact with the environment, are at the forefront of this transformation. They can monitor health metrics, respond to temperature changes, and even improve comfort and performance in athletic wear. A study by Grand View Research noted that the wearables market is expected to expand significantly, with an estimated revenue of $62 billion by 2025. This rise underscores the trend of fashion merging with technology, illustrating how today’s consumers prioritize not just aesthetics but also practicality and performance in their clothing. As designers continue to explore the potential of these textiles, the boundaries of fashion are being redefined, creating a more dynamic and interactive wardrobe for consumers.

Sustainability Advancements: Technology's Role in Eco-Friendly Textiles

The textile industry is undergoing a significant transformation, thanks to technological advancements that emphasize sustainability. Innovations such as digital printing, automated weaving, and the use of biodegradable materials are paving the way for eco-friendly textiles. These technologies not only reduce waste but also lower energy consumption, making the production process more efficient. For instance, digital printing requires less water and dye compared to traditional methods, resulting in a lower environmental footprint.

Tips for consumers interested in supporting eco-friendly textiles include seeking out brands that utilize sustainable practices, such as sourcing materials responsibly and implementing recycling programs. Additionally, consumers can look for certifications on products that indicate a commitment to sustainability, ensuring that their choices contribute to a healthier planet.

Another intriguing development is the rise of smart textiles, which integrate sensors and other technologies into fabric. While these innovations enhance functionality, they also pose the challenge of ensuring that the materials used are sustainable and non-toxic. As the industry continues to evolve, the focus on sustainability through technology is crucial not only for environmental wellbeing but also for meeting the growing consumer demand for ethical production practices. By embracing these advancements, the textile industry can move towards a more sustainable future.

Data Analytics and AI: Transforming Supply Chain Management in Textiles

Data analytics and artificial intelligence (AI) are revolutionizing supply chain management in the textile industry, providing unprecedented insights and efficiencies. By analyzing vast amounts of data, companies can predict trends, manage inventory effectively, and respond swiftly to consumer demands. For instance, machine learning algorithms can forecast material needs based on historical sales data, allowing manufacturers to reduce waste and optimize production schedules. This data-driven approach not only enhances operational efficiency but also ensures that companies remain competitive in an ever-evolving market.

Moreover, AI-powered tools facilitate real-time monitoring of supply chain activities, helping stakeholders to identify bottlenecks and potential disruptions. Advanced analytics enable textile businesses to assess supplier performance, ensuring quality and adherence to deadlines. With the integration of smart technologies, such as IoT devices, real-time tracking of materials is achievable, providing transparency and confidence throughout the supply chain. Consequently, this technological transformation not only enhances productivity but also builds stronger relationships with suppliers and customers alike, ultimately leading to sustainable growth in the textile sector.

Future Trends: Innovations Shaping the Textile Industry through Technology

The textile industry is undergoing significant transformation due to rapid technological advancements, which are reshaping its operational landscape. One of the most notable innovations is the integration of automation and artificial intelligence (AI) in manufacturing processes. According to a report by the McKinsey Global Institute, the adoption of AI in the textile sector could increase productivity by up to 40% in the next five years. Automating tasks such as cutting, sewing, and quality control not only speeds up production but also reduces human error, leading to higher quality products at lower costs.

Moreover, sustainable practices are increasingly being driven by technology, with innovations such as 3D printing and digital textiles playing a crucial role. A study from the Textile Research Journal highlights that 3D printing can reduce material waste by as much as 90%, revolutionizing how garments are designed and produced. Additionally, smart textiles that incorporate sensors and connectivity are gaining traction, offering functionalities like temperature regulation and enhanced durability. This convergence of technology and sustainability is not only appealing to consumers but also aligns with global goals for reducing environmental impact.

According to the World Economic Forum, sustainable practices in the textile industry could generate a $1 trillion market by 2030, underscoring the importance of technological innovations in shaping the future of textile production.

Related Posts

-

2025 Top 5 Innovations Transforming the Textile Industry You Need to Know

-

Top 10 Benefits of Using Staple Yarns for Your Next Project

-

10 Best Practices in Textile Manufacturing for Sustainable Production

-

5 Essential Tips on Understanding Types of Acrylic Fiber for Optimal Use

-

Exploring the Future of Textile Manufacturing: Sustainable Innovations Revolutionizing the Industry

-

Top 10 Benefits of Using Acrylic Textile in Fashion and Home Decor