Top Challenges in Textile Manufacturing and How to Overcome Them

Textile manufacturing is a vital sector that significantly contributes to global economies and employment. However, the industry faces a myriad of challenges that can hinder productivity and sustainability. Among these challenges are issues related to supply chain management, technological advancements, and environmental regulations. As manufacturers strive to maintain competitiveness while addressing these difficulties, innovative solutions and strategic approaches are essential.

The complexities of textile manufacturing require a thorough understanding of both traditional methods and modern innovations. For instance, fluctuations in raw material costs, labor shortages, and the need for sustainable practices have become pressing concerns. Additionally, rapid technological changes and consumer demands for quicker turnarounds and customized products necessitate agile responses from manufacturers. Therefore, overcoming these challenges not only ensures operational efficiency but also positions businesses for future success in a dynamic marketplace.

This article delves into the top challenges facing textile manufacturing today and explores effective strategies to mitigate these obstacles. By adopting innovative practices, fostering collaboration across the supply chain, and prioritizing sustainability, companies can navigate the intricacies of the textile industry and emerge stronger in a competitive landscape.

Overview of Textile Manufacturing Challenges

The textile manufacturing industry faces a multitude of challenges that impact efficiency, sustainability, and overall production quality. One of the primary issues is the reliance on outdated technology and processes. According to a report by McKinsey, approximately 90% of textile manufacturers still rely on traditional machinery, which results in lower operational efficiency and increased production costs. In the age of Industry 4.0, companies that fail to adopt automated solutions and advanced technologies may find themselves at a distinct disadvantage.

Additionally, the industry grapples with supply chain disruptions, a challenge exacerbated by the recent global pandemic. A survey conducted by Deloitte found that 70% of textile manufacturers experienced significant delays in sourcing raw materials due to logistical issues. This not only threatens production timelines but also inflates costs, as companies seek alternative suppliers or expedite shipping methods to meet demand. Furthermore, sustainability has emerged as a pressing concern, with consumers increasingly demanding eco-friendly practices. The Ellen MacArthur Foundation reports that only 1% of the textiles produced globally are recycled, highlighting the need for innovative recycling methods and circular economy practices to meet expanding environmental standards. Addressing these challenges through technology adoption, supply chain diversification, and sustainable practices will be crucial for the future resilience of the textile manufacturing sector.

Supply Chain Disruptions and Their Impact on Production

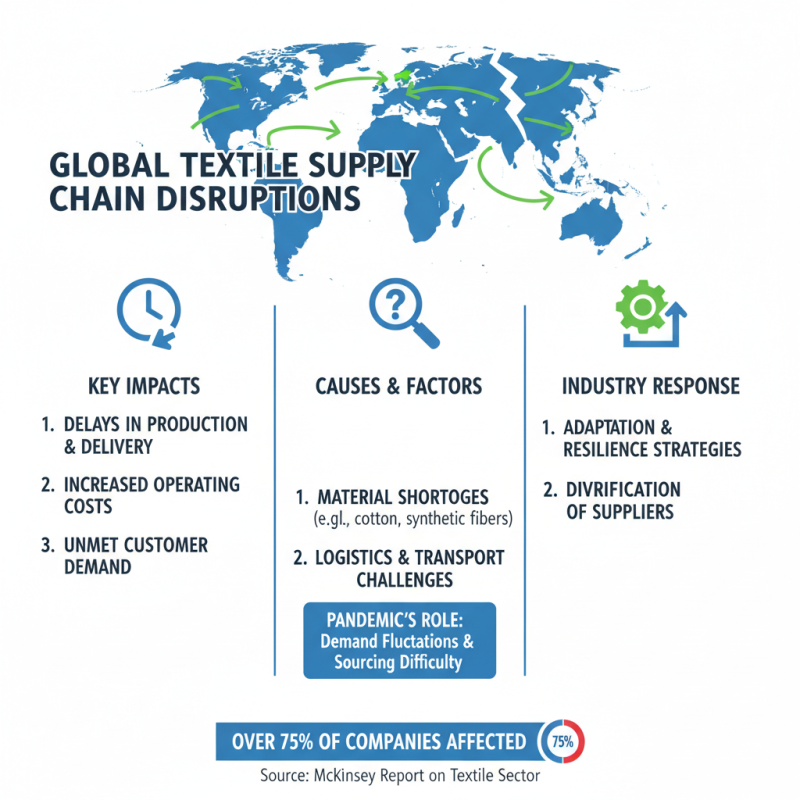

Supply chain disruptions have significantly impacted the textile manufacturing industry, leading to delays, increased costs, and unsatisfied customer demands. According to a report by McKinsey, over 75% of companies in the textile sector reported supply chain interruptions due to factors such as material shortages and logistics challenges. The pandemic has exacerbated these issues, causing significant fluctuations in demand and making the sourcing of raw materials increasingly difficult. As textile manufacturers strive to adapt, understanding and mitigating these disruptions has become crucial.

One effective strategy to counteract supply chain challenges is to diversify supplier sources. Relying on a single supplier can lead to major setbacks in production if that supplier encounters issues. Industry experts recommend establishing relationships with multiple suppliers across different geographical regions. Additionally, employing advanced analytics can enhance visibility throughout the supply chain, allowing manufacturers to predict potential disruptions and respond proactively.

**Tips:** Regularly review and update supplier contracts to include flexibility clauses that can alleviate the impact of uncertainties. Invest in technology that provides real-time data on supply chain health to optimize decision-making processes. By doing so, manufacturers can better navigate the complexities of supply chain management while minimizing disruptions.

Labor Shortages and Skills Gap in the Textile Industry

The textile industry faces significant challenges, particularly regarding labor shortages and the skills gap. As the demand for skilled workers continues to grow, many manufacturers are struggling to find appropriate talent. This shortage is compounded by the aging workforce and a lack of interest among younger generations to pursue careers in this sector. The result is not only a dwindling number of experienced professionals but also a gap in essential skills required for modern textile production techniques, including advanced machinery operation and quality control processes.

To bridge this gap, the industry must invest in training and development programs that attract new talent and enhance the skills of existing workers. Implementing apprenticeship and internship programs can provide hands-on experience and help cultivate interest in the field among young people. Additionally, partnerships with educational institutions can ensure that the curriculum aligns with industry demands, equipping students with relevant skills before they enter the workforce. By fostering a culture of continuous learning and adapting to technological advancements, companies can address labor shortages and close the skills gap effectively.

Sustainability Issues and Environmental Regulations

The textile manufacturing industry faces significant sustainability challenges, primarily driven by increasing environmental regulations. These regulations compel manufacturers to adopt more eco-friendly processes, which can be daunting for companies accustomed to traditional practices that may not prioritize environmental impact. To navigate these challenges, manufacturers must reassess their operations and embrace sustainable practices that minimize waste and reduce carbon footprints.

Tip: Implementing a closed-loop system can drastically reduce waste in textile production. This method involves recycling materials at the end of their life cycle to create new textiles, thereby conserving resources and decreasing environmental impact. Additionally, investing in renewable energy sources for production facilities can help meet regulatory requirements while simultaneously lowering operating costs.

Another pressing issue is the need to comply with strict environmental regulations regarding chemical use and waste management. These regulations require transparency and accountability within the supply chain. Companies must invest in training programs for employees to ensure compliance and adopt a proactive approach to sustainability.

Tip: Collaborating with eco-friendly suppliers can facilitate adherence to environmental regulations. Engaging in partnerships with organizations that prioritize sustainability not only enhances supply chain transparency but also strengthens a company’s reputation in an increasingly eco-conscious market.

Top Challenges in Textile Manufacturing and How to Overcome Them

| Challenge | Impact | Solution | Benefits |

|---|---|---|---|

| Water Usage | High environmental impact and cost | Implement water recycling systems | Reduced water consumption and costs |

| Chemical Waste | Pollution and possible fines | Invest in biodegradable chemicals | Improved sustainability and brand image |

| Energy Consumption | Increased production costs | Adopt energy-efficient machinery | Lower energy bills and carbon footprint |

| Labor Practices | Reputation risks and compliance issues | Enhance worker rights and safety measures | Better employee satisfaction and legal compliance |

| Supply Chain Disruptions | Delays and increased costs | Diversify suppliers and local sourcing | Increased resilience and reduced risk |

Technological Advancements and Their Role in Overcoming Challenges

In the textile manufacturing industry, challenges such as labor shortages, sustainability pressures, and inefficiencies in production processes are prevalent. These challenges, however, are being increasingly addressed through technological advancements. According to a recent report from the Textile World, automation and smart manufacturing technologies are projected to enhance productivity by over 20% by 2025. This evolution not only streamlines operations but also minimizes human error, ensuring a more consistent quality in production.

Moreover, the integration of artificial intelligence (AI) and machine learning in textile manufacturing processes has shown tremendous promise in optimizing supply chains. A study by McKinsey indicates that AI could potentially generate $600 billion in value for the fashion and textile sector by improving demand forecasting and inventory management. These technologies enable manufacturers to respond more agilely to market trends, reducing waste and contributing to sustainable practices. By embracing these advancements, textile manufacturers can navigate the current landscape more effectively while also addressing the industry's pressing challenges.

Related Posts

-

Exploring the Future of Textile Manufacturing: Sustainable Innovations Revolutionizing the Industry

-

Top 10 Benefits of Using Staple Yarns for Your Next Project

-

2025 Top 5 Innovations Transforming the Textile Industry You Need to Know

-

5 Essential Tips on Understanding Types of Acrylic Fiber for Optimal Use

-

Exploring the Different Types of Textile Fibers: A 2025 Guide to Fabrics

-

2025 Top Yarn Acrylic Options for Every Craft and Project