How to Use Staple Fibers in Textile Production?

In the textile industry, staple fibers play a crucial role in production. These short fibers, typically ranging from 1 inch to several inches, are essential for creating various fabrics. According to a 2022 report by the Fiber Science Institute, staple fibers account for nearly 70% of the global fiber market. However, many manufacturers overlook the importance of proper staple fiber selection.

A significant challenge is sourcing quality staple fibers. The blend of synthetic and natural fibers often complicates production processes. Yet, understanding specific client needs can lead to better outcome decisions. Though standardization exists, not all staple fibers are created equal. For example, cotton fibers are valued for softness, while polyester offers durability.

Incorporating staple fibers effectively requires knowledge and skill. Manufacturers must consider fiber length, blend composition, and spinning techniques. Textile production can fail without this focus. Rethinking current strategies could enhance quality and reduce waste. The industry must reflect on these elements to improve overall outcomes.

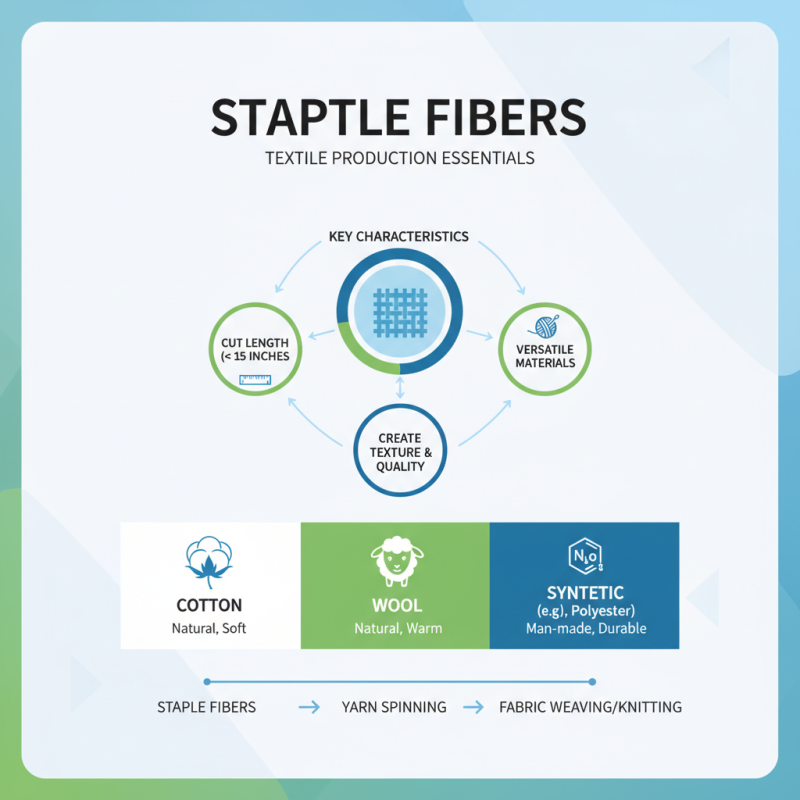

Understanding Staple Fibers and Their Characteristics

Staple fibers play a crucial role in textile production. They are fibers cut to a certain length, often less than 15 inches. Cotton, wool, and synthetic fibers like polyester are common examples. Their length and inherent characteristics make them unique. Staple fibers create yarns and fabrics with different textures and qualities.

When using staple fibers, consider the type and length. Shorter fibers can lead to a softer fabric, while longer fibers offer durability. Blending fibers can enhance the final product. For instance, combining cotton and polyester can yield a fabric that is both breathable and resilient.

**Tips:** Always test small samples before large-scale production. This allows for adjustments to be made. Also, consider the environmental impact of your chosen fibers. Are they sustainable and can they be recycled? These are important questions to ask during the production process.

Types of Staple Fibers Used in Textile Production

Staple fibers are essential in textile production. They provide the backbone for fabrics used worldwide. Common types include cotton, wool, and synthetic fibers.

Cotton is one of the most populous fibers, accounting for about 24% of global fiber consumption in 2020.

Wool, valued for its insulation properties, constitutes roughly 1% of the market but remains vital for high-quality garments.

Synthetic staple fibers also play a significant role. Polyester, for instance, has gained increasing popularity. In 2021, polyester fibers made up over 50% of global fiber production, surpassing natural fibers.

The flexibility and durability of these fibers often appeal more to manufacturers. However, their environmental impact raises concerns among industry experts.

Not all staple fibers are created equal. While some offer superior performance, others may fall short. Natural fibers can vary in quality significantly, depending on factors like growing conditions and processing methods.

For synthetic options, the process of recycling is not yet fully realized. These challenges prompt continuous discussion on the sustainability of staple fiber production in the textile industry.

Processing Staple Fibers for Fabric Manufacturing

Processing staple fibers for fabric manufacturing involves several steps. These fibers are short and can be made from natural or synthetic materials. The most common types include cotton, wool, and polyester. Each fiber type has its unique properties and uses in textiles.

The first step is cleaning the fibers. This involves removing dirt and impurities. After cleaning, the fibers are often carded. Carding aligns the fibers and helps in removing any remaining debris. This process is crucial for ensuring a smooth fabric texture. Once carded, fibers can be blended to achieve desired properties. Blending various fibers can offer improved strength, softness, or moisture-wicking abilities.

Next comes spinning, where the carded fibers are twisted together to create yarn. The yarn can vary in thickness, depending on the intended fabric. It is vital to monitor the spinning tension. Too tight could lead to brittleness; too loose may cause fabric weakness. Finally, the yarn can be woven or knitted into fabric. But there are challenges. Not all blends work well together. Some combinations may lead to inconsistent quality. This aspect requires careful thought and testing.

How to Use Staple Fibers in Textile Production? - Processing Staple Fibers for Fabric Manufacturing

| Fiber Type | Length (mm) | Applications | Processing Method | Advantages |

|---|---|---|---|---|

| Cotton | 20-50 | Apparel, Home Textiles | Spinning, Weaving | Soft, Breathable |

| Wool | 30-150 | Outerwear, Scarves | Carding, Spinning | Insulating, Durable |

| Polyester | 38-64 | Sportswear, Home Furnishings | Melt Spinning, Weaving | Strong, Moisture-Wicking |

| Viscose | 25-45 | Dresses, Linings | Dissolving, Spinning | Silky, Comfortable |

| Nylon | 30-60 | Activewear, Hosiery | Extrusion, Weaving | Elastic, Strong |

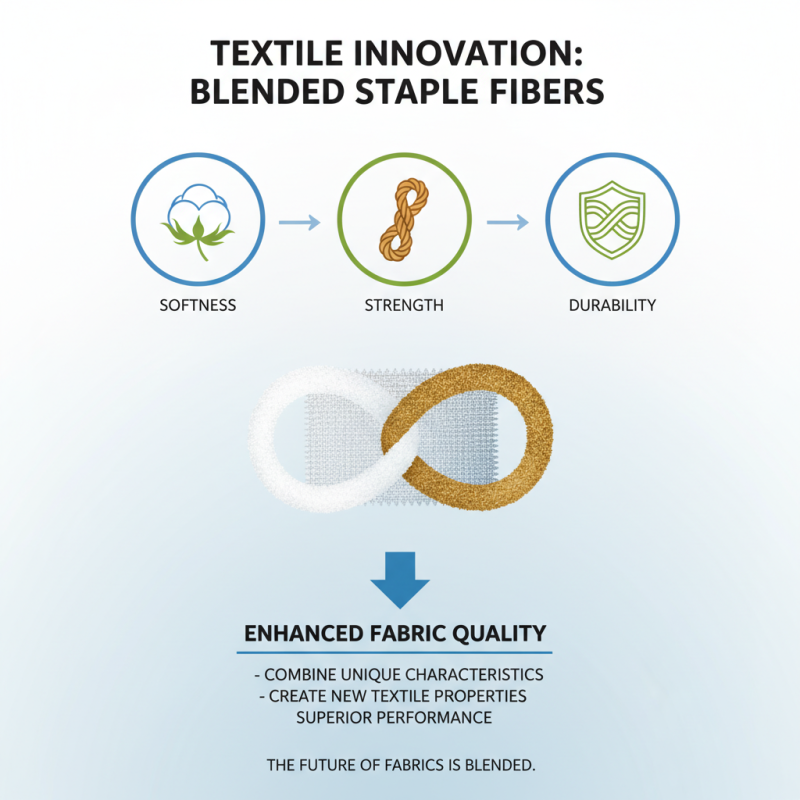

Techniques for Blending Staple Fibers in Textiles

Blending staple fibers in textile production can enhance fabric quality. Different fibers have unique characteristics. By combining them, we can create fabrics that are softer, stronger, or more durable.

One common technique is carding. This process separates staple fibers and aligns them. It allows for even mixing. However, achieving perfect blend ratios can be tricky. Sometimes, the fibers don't mix as expected. This requires adjustments in the process and careful monitoring of the output.

Another method is blending during spinning. This involves adding fibers to the spinning frame. The result is a yarn that has qualities of both fibers. Yet, this method can lead to inconsistencies in texture. It's essential to test different blends to find the right combination for the desired end product. Understanding the properties of each fiber can greatly affect the outcome.

Quality Control and Testing of Staple Fiber Fabrics

Quality control in the production of staple fiber fabrics is crucial. It ensures the final product meets consumer expectations. Testing methods can vary but often include visual inspections, strength tests, and dye consistency evaluations. These steps help identify defects early, preventing costly rework later.

During the testing phase, some issues may arise. For instance, inconsistent fiber lengths could affect the fabric's texture and strength. Inspectors must be vigilant. However, human error is always a possibility. Sometimes flaws go unnoticed until after the fabric is produced, leading to wastage.

Regular audits and feedback loops can enhance the quality control process. This approach allows for the adjustment of production techniques. Equipment calibration is also vital to maintain consistency. In an industry focused on efficiency, prioritizing thorough testing can sometimes feel tedious. Yet, it’s necessary for producing durable, high-quality textiles that truly satisfy consumers.

Related Posts

-

2025 Top Yarn Acrylic Options for Every Craft and Project

-

2025 How to Choose the Best Yarn Acrylic for Your Next Knitting Project

-

Unlocking the Benefits of Acrylic Fiber: Why It's the Future of Sustainable Fashion

-

How to Identify Different Types of Textile Fibers for Your Projects

-

What is the Impact of Technology on the Textile Industry Today

-

Top 5 Benefits of Polyester Fiber for Home and Industrial Use